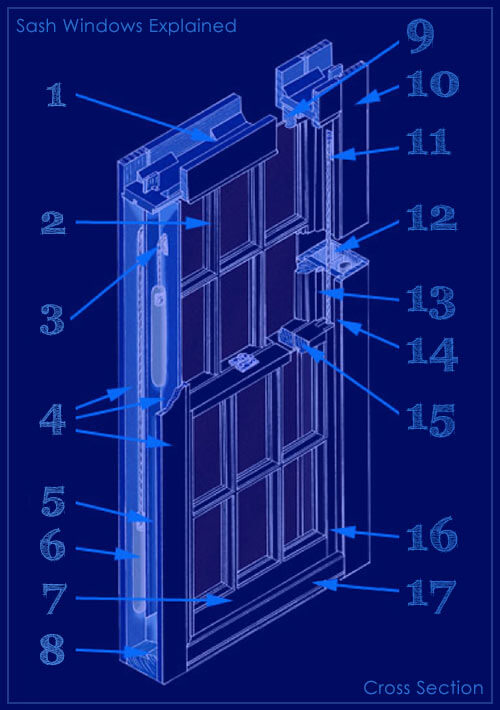

Sash Windows Explained

- Has someone told you that your Wag Tail is faulty?

- Don’t know your Parting Bead from your Staff Bead?

- Do you want to know what’s happening inside your sash?

Grab a coffee and study the below blueprint for the answers.

1. Soffit Lining. The head of the window is made up of main inner and outer Timber Linings (4) and a separate Soffit Lining. Strength is added via glued triangular blocks.

2. Glazing Bar. Vertical and horizontal framing members that divide the panes within the Rails and Stiles.

3. Pulley Wheel. The pulley mortised in the top of the Pulley Lining. The Sash Cord (11) will pass over it and counterbalance the Weights (6).

4. Timber Linings. Sections that form casings of the Box Frame (10). These are hollow and house the Weights (6) and are made in three parts: the ‘outer’, ‘inner’ and ‘pulley’ linings.

5. Wag Tail. Strip of timber inside the Box Frame (10) separating the Weights (6). This can also be called a ‘parting slip’.

6. Weight. To counterbalance each sliding sash a pair of lead weights are hung on the Sash Cord (11). The weights and sash must be if equal weight.

7. Bottom Rail. Horizontal bottom framing member.

8. Box Cill. Internally fitted horizontal bottom section of the frame at the base of the sashes. Correctly shaped the water will flow away to the outside.

9. Top Rail. Horizontal top framing member.

10. Box Frame. This can also be known as a ‘jamb’. The main box frame will be made up of three Timber Linings (4).

11. Sash Cord. The sash cord runs over the Pulley Wheel (3) holding the Weights (6). Some sash windows have Spiral Balancers instead.

12. Weight Pocket. The cavity inside the Timber Linings (4) either side of the window where the Weights (6) hang.

13. Parting Bead. A narrow and long seal that fits vertically in the Box Frame (10) forming separate channels for the upper and lower sashes to run in, holding the top sash in position.

14. Staff Bead. Moulded section of timber made of four sections. Once pinned around the Box Frame (10) air tightness can be achieved when draught proofed. Staff bead will also hold the bottom sash in position.

15. Meeting Bars / Rails. Horizontal framing members meeting the two sashes together in the middle.

16. Stile. One vertical vertical side framing member each side of the sash.

17. Apron. Decorative cladding or panel found beneath the window. Not all sash boxes having an Apron.

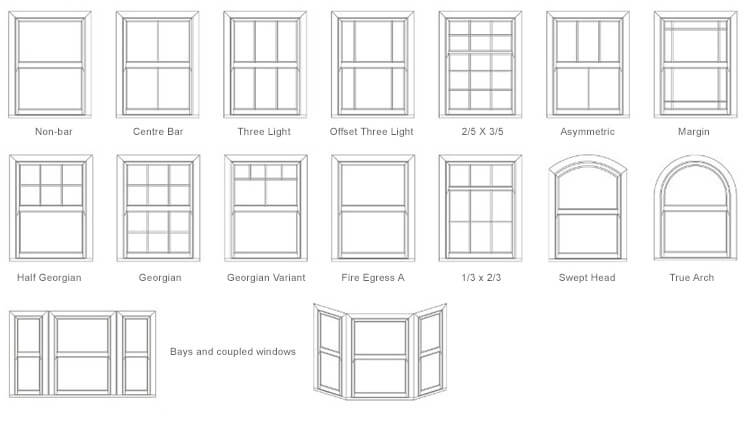

Types And Styles Of Sash Window

There are many types and styles of sash windows, we are able to create the variant that suits your property.

U-values

A “U-Value” is a rating that describes the performance of your window. The lower the U-Value the better. And so for example 1.8 is a very high performance, and 1.1 is exceptionally good.

Such a rating system allows us to grade how easily heat can be lost through parts of a building, and of course through windows. We have seen building regulations gradually increase insulation standards, and the level of insulation will depend on the date the building warrant was issued, and not when the building was constructed.

It wasn’t until 1991 that there were requirements for window insulation and until then windows had U-Value in the region of 4.8. By 2002 regulations required windows with wood or PVC frames to have a U-Value of 2.0, and those with metal frames a U-Value of 2.2 – or lower if a boiler was old or inefficient. By 2010 we now see a U-Value of 1.6.

Contact Us For An Accurate Quote

Each quotation we supply is tailored to our customer’s individual requirements. The replacement windows are bespoke built in order to ensure an authentic reproduction. Get in touch with our friendly team for a free estimate on any of the services we offer. Either click the link to the right of this page or call us today on 02082969487. Alternatively, you can email our team at info@sjbsashwindows.co.uk.